Fiber laser is used in sheet metal processing, aviation, aerospace, electronics, electrical appliances, subway accessories, automobiles, food machinery, textile machinery, engineering machinery, precision accessories, ships, metallurgical equipment, elevators, household appliances, craft gifts, tool processing, decoration, advertising, Metal processing, kitchenware processing, and other manufacturing and processing industries.

At present, the primary function of fiber laser is that sheet metal processing: laser cutting, welding, marking, and cleaning.

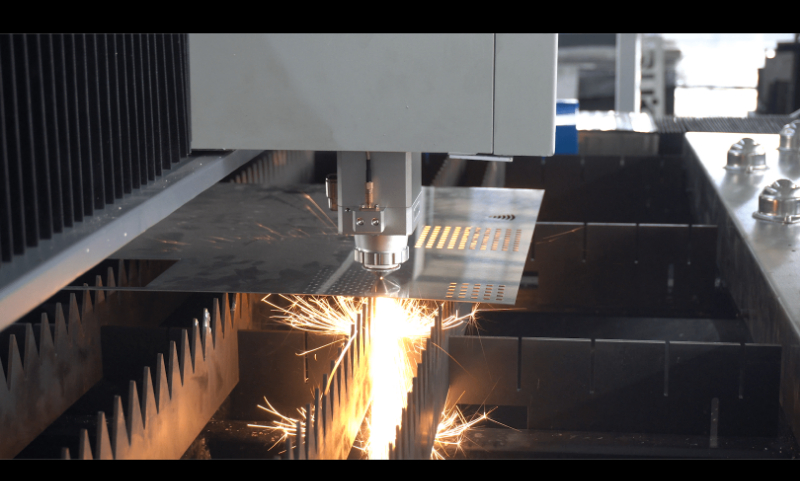

Laser Cutting

0.5 – 25 mm metal

The most stable and continuous production thickness is 0.5-25 mm, laser power is from 1 kW to 10 kW.

The higher the laser power, the faster the cutting speed when you cut metal materials of the same thickness.

Fiber laser is an essential part of fiber laser cutting machines.

With the continuous improvement of fiber laser power and the constant maturity and expansion of the laser processing market, fiber laser cutting machines are increasingly used in the sheet metal processing industry.

Laser Welding

With the development of science and technology and higher requirements for environmental protection, laser welding technology has been continuously improved.

In the 21st century, laser welding, as a high-quality, high-precision, low-deformation, high-efficiency, and high-speed application technology, has gradually become an indispensable tool for metal material processing and manufacturing.

Laser Cleaning

Laser cleaning machine, including continuous fiber cleaning machine and pulsed fiber laser cleaning machine.

Laser cleaning technology is widely used in various industries, and the details are as follows: Surface treatment: surface roughening, pre-welding treatment, etc.; Paint rust removal: aircraft, ships, weapons, etc.

Laser Marking

Laser marking technology is one of the most prominent application fields and one of the most mature fields of laser processing.

Laser marking is a marking method in which the laser partially irradiates the workpiece to discolor or vaporize the surface material, thereby leaving a permanent mark.

The laser marking pattern has a wide range, and the minor character can reach 0.1mm, which is vital for the product’s brand anti-counterfeiting.

Top 5 Advantages of a Fiber Laser Cutting Machine

1. Better cutting-edge quality.

A thinner beam makes the energy more tightly focused, which means sharper edges.

The fiber laser cutter can cut excellent sheet metal parts and does not require secondary processing. In addition, less heat into the metal can reduce metal deformation.

Therefore, the metal parts can be more suitable for nesting cutting, reducing waste, and reducing the production cost of a single piece to a greater extent.

2. Cut reflective materials such as aluminum and copper.

Compared with CO2, fiber laser cutting is faster and more reliable.

3. Adjustable piercing and cutting speed.

Higher power and smaller spot size will make the “penetration” time shorter. If many holes need to be penetrated in the cutting workpiece, high-power cutting opportunities will make your cutting work more efficient.

Think about it, if you save 1-2 hours a day, is it inspiring?

4. Workable to cut sheets and tubes.

Using a cutting machine, we can cut metals with a thickness of up to 25 mm.

Metal types are stainless steel, carbon steel, alloy steel, silicon steel, spring steel, aluminum, aluminum alloy, galvanized sheet, aluminum zinc sheet, pickling sheet, copper, silver, gold, titanium, and other metal plates and pipes.

5. Nesting function is available.

Due to the small thermal deformation of the fiber laser, a small gap between the workpieces is allowed. With the use of nesting software, fiber laser cutters can achieve high material utilization.

When you join the sheet metal processing industry, a fiber laser cutting machine is your only choice. Because in such a competitive resource environment, fiber laser cutting can let you stand out in the increasingly fierce competition.

Our current end-user community is happily using our machines in several industries. Industries include kitchenware, signage, market rack, door, metal fabrication, etc.

Leave your message if you have any doubts or need any help~