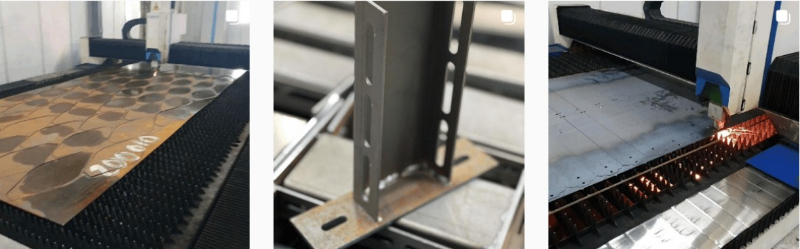

Fiber-optic laser cutters are becoming increasingly popular in the metal-working industry thanks to their advantages over older cutting machines: faster, more accurate, and less energy consumption. This cutting tool is used in a variety of applications, including:

1. Metal fabrication

Laser cutting machines have a wide range of cuttable material types, material shapes, and material thicknesses. For example, material types include carbon steel, stainless steel, brass, aluminum alloy, etc., with thicknesses from 0.5mm to 80mm, and shapes like sheet metal and tubes.

With the fiber laser cutter, metal fabricators can achieve better precision and use less energy than conventional sheet metal processing equipment.

Traditional sheet metal cutting equipment includes shearing, punching, flame-cutting, plasma cutting, high-pressure water cutting, and other conventional sheet metal processing equipment.

With the development of laser technology, they are applying high-power laser cutting machines in various industries, gradually replacing traditional metal cutting tools.

2. Machinery industry

Agricultural machinery or construction machinery requires sheet metal cutting machines to process cutting fuselage and parts.

One benefit of a fiber laser cutter is that it will not cause extrusion and deformation of metal materials.

Machinery includes tractors, trailers, rotary tillers, planters, fertilizer machines, irrigation machines, Baling machines, and agricultural products processing machines.

3. Shipbuilding industry

“Precision shipbuilding” and “fast shipbuilding” have become the main trends in the shipbuilding industry’s development.

The fiber laser cutting machine could cut thicker steel, with precision cutting to make no on-site trimming, reducing labor and material waste.

4. Decoration and advertising industry

Due to the high speed and flexible cutting of the fiber laser cutter, many complex graphics can be quickly identified and processed by an efficient fiber laser cutting system. The cutting effects have won the favor of decoration companies.

Cutting system and graphics software compatibility are very high, which makes the custom advertising business more flexible and efficient.

Advertisement products include decorative doors, wall paintings, glowing characters, signage, outdoor billboards, bus stop signs, light boxes, and so on.

5. Elevator industry

The elevator industry needs to cut the stainless steel sheet, which is covered with film, and various steel plates and pipes. Thanks to its stainless steel cutting results, have the advantages of surface smoothness and no oxidation of the cutting surface. More elevator metal parts manufacturers are more inclined to the fiber laser cutter.

Metal parts include elevator decor, frame, escalator pedals, and panels.

6. Mechanical cabinets

Mechanical cabinets are popular in various industries, and the demand for their quality has become increasingly high also.

And the fiber laser cutter will meet the strict needs of the metal sheet cutting requirements.

7. Fitness equipment

The demand for fitness equipment is getting higher, and various new equipment is emerging.

Fiber laser tube cutters could cut round and square tubes or shaped pipes such as oval pipes, bread pipes, etc., which could be used in fitness equipment. And high-precision cutting finish will shorten the production cycle of the fitness device. And it’s advantages meet the need to innovate and develop new products.

Fitness equipment includes commercial fitness equipment, strength equipment, treadmill, aerobic exercise equipment, and sports equipment.

8. Kitchenware industry and home appliance industry

Cutting thin stainless steel with faster speed, high precision, sound effect, and smooth cutting surface, all of these advantages of a fiber laser cutter will help the client to realize better customized and personalized product development.

Sheet metal cutting is needed for kitchenware and home appliance industries. The fiber laser cutting machine will improve the processing quality, optimize the device’s appearance, reduce costs and improve efficiency.

The final products include range hoods, gas burners, stovetops, cabinets, gas stoves, steam cabinets, induction cookers, microwave ovens, sizeable commercial kitchenware, etc.

9. Rail transportation industry

Laser cutting technology is mainly used in rail vehicle manufacturing, plate, and profile cutting, like cutting cases of bogie boards.

10. Automobile industry and aerospace

Many plane metal parts of the automobile need flat sheet metal cutting.

Fiber laser cutting machine has the incomparable flexibility and processing precision of the traditional cutting processing method.

Sheet metal parts include automobile chassis, cab doors, sheet metal shells, brake pads, connectors, and so on.

Do laser-cutting machines have an advantage in your industry?

Whether it is suitable to apply the laser cutting machine to your industry? You could check your cutting requirements and the following points.

1. Compared with the traditional flame cutting, the laser cutting machine has the advantages of plasma cutting energy concentration, slight deformation of the workpiece, and good cutting surface (even as the last process), at the same time with cutting material light, less pollution and other advantages, in the concept of environmental protection in People’s hearts today, has incomparable advantages.

2. The fiber laser cutter has advantages Compared with traditional punching, shearing, drilling, and other processing technology.

- High efficiency (high cutting speed)

- Low cost-effectiveness (no need for mold making and low power consumable)

- Strong adaptability (can process complex and changeable parts)

- High precision cutting (processing parts with high quality)

- Need fewer processing steps (Good cutting finish and no need for further finish processing)

3. Its shortcoming is the upfront investment is slightly oversized.